Blog

TEKNOPALAS

Keep following us to be informed about all developments in the field of RFID and IoT. New information and new solutions coming soon…

How to Make Access Control System with RFID

Access Control System: Safe and Practical Solutions

RFID (Radyo Frekansı Tanımlama) geçiş kontrol sistemi, belirli alanlara erişimi yönetmek ve izlemek için kullanılan modern bir teknolojidir. Bu sistem, kullanıcıların kimliğini radyo dalgaları ile tanımlayarak, hızlı ve güvenli bir geçiş sağlar. İşte RFID geçiş kontrol sisteminin temel bileşenleri ve işleyişi hakkında detaylı bilgi:

1. Components of an RFID Access Control System

An RFID access control system consists of several main components:

- RFID Cards or Tags: These cards carry the user’s identity information. They typically come in the form of a plastic card or key fob.

- RFID Readers: These devices read the user cards. Readers detect the data on the card through radio waves.

- Software: Software that manages access control. It stores user information and determines whether to grant or deny access.

- Door Control Devices: Access mechanisms such as electronic locks or turnstiles that integrate with RFID readers.

2. How RFID Access Control Systems Operate

When the user brings the RFID card close to the reader, the system is activated. The reader detects the information on the card and sends it to the software. The software checks whether the user is registered in the system. If the user is registered, access is granted; otherwise, access is denied.

3. Advantages of RFID Access Control Systems

RFID access control systems offer fast and easy usage. Users can instantly gain access by scanning their cards. They also provide high security, as cards can be protected with encryption. Automatic tracking allows entry and exit data to be recorded, which is useful for security and management purposes.

4. Application Areas of RFID Access Control Systems

RFID access control systems are used in various areas, such as office buildings, universities, hospitals, hotels, shopping malls, and industrial facilities. These systems not only enhance security but also improve the user experience.

RFID access control systems hold a significant place among modern security solutions. They provide effective security for both businesses and individuals.

RFID Access Control Systems Result

RFID (Radio Frequency Identification) access control systems play an important role in modern security applications. These systems stand out with the advantages they provide while managing access to specific areas. Here are the results and impacts of RFID access control systems:

2. Fast and Easy Access

Users can quickly gain access by scanning their RFID cards. This is especially beneficial in high-traffic areas, saving time. The absence of physical keys or passwords further accelerates the process.

3. Automated Tracking and Reporting

RFID systems automatically record entry and exit data. This provides security professionals and administrators with detailed reports on user movements. This information is valuable for security analysis and access adjustments.

4. Flexible Application Areas

RFID access control systems can be used in various areas such as offices, universities, hospitals, hotels, and industrial facilities. This flexibility allows the system to be tailored to different needs.

5. Cost-Effectiveness

Although RFID systems require an initial investment, they offer cost-effective solutions in the long run. Automated tracking and management reduce staffing needs and lower operational costs.

Why Should RFID Be Used in Cold Chain Transportation?

In Cold Chain Transportation, RFID technology plays a crucial role in maintaining appropriate temperature conditions, especially for perishable goods. RFID (Radio Frequency Identification) technology provides significant advantages in this process:

Temperature Monitoring: RFID tags equipped with temperature sensors continuously track temperature fluctuations. This feature offers an effective solution for maintaining quality and freshness economically.

Data Accuracy and Traceability: RFID tags securely store and transmit data, ensuring reliable traceability throughout the cold chain. This enhances compliance and strengthens the overall cold chain integrity.

Process Automation: RFID technology automates processes related to warehouse management, product continuity, and quality control. This leads to increased efficiency and cost savings.

Enhanced Security: RFID tags provide security against threats such as tampering and unauthorized access. They prevent interference with the tags, ensuring maximum product safety.

Exception Management: RFID technology detects deviations in temperature or other critical metrics, triggering real-time alerts. This helps prevent spoilage and facilitates prompt action.

Features of RFID Temperature Sensors

Teknopalas’ specialized RFID and NFC tags offer unique features for maintaining the cold chain:

Lightweight and Compact Design: The tags are only 1 mm thick and can be designed as either a shipping label or a card.

Adjustable Logging Intervals: Temperature recording intervals, alarm levels, and similar parameters can be customized for each tag and updated as needed.

High Data Storage Capacity: Temperature data can be stored offline within the chip and accessed easily via the cloud.

Multiple Reading Methods: Users can read temperature logs using fixed readers, handheld readers, or NFC-enabled smartphones.

Long Battery Life: The system optimizes and adjusts the battery life of the tags to meet specific requirements.

Wide Temperature Recording Range: The tag records temperatures from -30°C to +50°C with ±0.25°C accuracy.

Ease of Tracking with Mobile App and NFC

Teknopalas RFID and NFC tags enable user-friendly cold chain tracking through a mobile application. By loading temperature data onto the app, users can monitor temperature changes from anywhere. Additionally, temperature data can be accessed seamlessly by tapping NFC-enabled phones to the tags.

Cloud-Based Data Integration

Our RFID and NFC tags provide options for temperature tracking, offline storage, and cloud uploading. This allows office staff to monitor the cold chain remotely, improving storage management. At Teknopalas, we offer businesses highly secure, accurate, and continuous monitoring systems with solutions such as RFID cold chain tracking and NFC cold chain monitoring. By ensuring reliable and efficient solutions with our RFID tags, we enhance success in cold chain logistics.

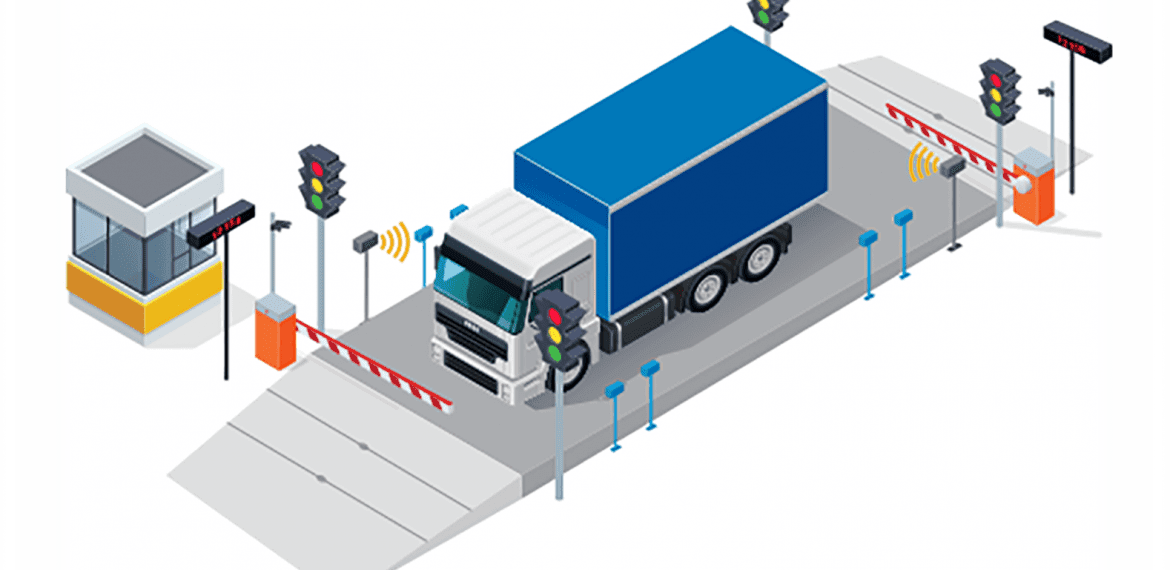

RFID Applications in Automated Weighing Systems

Automated weighing systems are increasingly used to improve efficiency and reduce the margin of error in industrial processes. One technology that enhances the efficiency and accuracy of these systems is Radio Frequency Identification (RFID) technology. In this article, we will explore RFID applications in automated weighing systems and the benefits this technology provides.

Introduction to RFID Technology

RFID technology uses electromagnetic fields to automatically identify and track tags attached to objects. These tags store electronically encoded information that RFID readers can scan without a direct line-of-sight. This feature makes RFID versatile and effective in various environments.

1. How RFID Enhances Automated Weighing Systems

Improved Accuracy and Efficiency

RFID technology enhances the accuracy of automated weighing systems by eliminating manual input errors and allowing precise data collection. This improvement leads to more reliable weight measurements and boosts operational efficiency by reducing the need for manual intervention.

Real-Time Data Collection

RFID enables real-time data collection as products pass through the weighing system. This allows for immediate processing and analysis, speeding up decision-making and providing timely responses to any discrepancies or issues.

2. Applications in Logistics and Supply Chain Management

Inventory Management

In logistics and supply chain management, RFID-integrated weighing systems simplify inventory tracking. As goods move through various stages, their weight is automatically recorded and updated in the inventory system. This ensures accurate stock levels and minimizes the risk of overstocking or stockouts.

Transportation and Shipping

RFID applications in transportation and shipping include automated weighing systems that verify the weight of packages and containers before loading them onto transport vehicles. These systems ensure compliance with weight regulations and optimize load distribution, improving safety and fuel efficiency.

3. Applications in Manufacturing and Production

Quality control

In manufacturing, RFID-enabled weighing systems play a crucial role in quality control. By continuously monitoring the weight of raw materials and finished products, manufacturers can ensure that each product meets the set weight criteria, reducing the possibility of defects and maintaining high quality standards.

Automatic Sorting and Packing

RFID improves automated sorting and packing processes by linking weight data with product information. This enables precise sorting by weight and guarantees accurate packaging. This is crucial in industries such as pharmaceuticals and food production, where precision is critical.

4. Practices in Agriculture and Livestock Management

Crop Yield Measurement

RFID-equipped weighing systems help accurately measure crop yields in agriculture. As farmers weigh harvested crops, the data is automatically recorded, assisting in monitoring productivity and making informed decisions on crop management and resource allocation.

Animal Weighing

In livestock management, RFID technology helps monitor the weight of animals. By attaching RFID tags to livestock, farmers can effectively track animal growth and health by automatically recording weight data during feeding or health checks.

5. Benefits of RFID in Automated Weighing Systems

Enhanced Traceability and Transparency

RFID provides enhanced traceability by linking weight data to specific RFID tags that can contain detailed information about the product or item. This transparency is beneficial for quality assurance, regulatory compliance and customer satisfaction.

Cost Savings and Increased Efficiency

The automation and accuracy brought by RFID technology delivers significant cost savings by reducing labor costs, minimizing errors and streamlining operations. Increased productivity results from faster processing times and reduced downtime.

6. Challenges and Considerations

Integration and Implementation Costs

Despite its advantages, integrating RFID into existing systems can be costly. The initial investment in RFID infrastructure, including tags, readers and software, as well as potential changes to existing processes should be carefully considered.

Data Security and Privacy

With the increasing use of RFID technology, data security and privacy have become critical concerns. Ensuring RFID systems are protected against unauthorized access and data breaches is essential to safeguard sensitive information and maintain trust.

7. RFID and Future Trends in Automated Weighing Systems

Developments in RFID Technology

Continued advances in RFID technology, such as increased read ranges, enhanced data storage capabilities and improved durability of tags, will further expand the applications and effectiveness of RFID in automated weighing systems.

Integration with IoT and Artificial Intelligence

The integration of RFID with the Internet of Things (IoT) and Artificial Intelligence (AI) promises to bring even greater innovation. IoT connectivity enables seamless data sharing between systems, while AI can optimize operations and decision-making by delivering advanced analytics and predictive insights.

Solution

RFID applications in automated weighing systems are transforming industries by providing accurate, real-time data, increasing efficiency and enabling traceability. As technology continues to evolve, the potential for RFID in weighing systems will grow, providing new opportunities for innovation and improvement across a variety of industries.

RFID Smart Production Solutions

In the fast-paced world of manufacturing, productivity is crucial. Every second counts, and every process must be optimized to maximize output. This is where RFID smart production solutions come in, revolutionizing manufacturing operations. This article explores the transformative impact of RFID technology on the future of manufacturing.

Understanding RFID Technology

RFID technology uses radio waves to identify and track objects, assets, and products in real time. It consists of tags attached to items, readers that collect data from these tags, and a system that processes the data. Unlike traditional barcodes, RFID tags don’t need a direct line of sight and can store much more data, making them ideal for manufacturing applications.

Advanced Asset Tracking and Management

One major advantage of RFID smart production solutions is the ability to track and manage assets throughout the production process. By tagging raw materials, components, and finished products, manufacturers gain real-time visibility into their inventory’s location and status. This improves inventory management, reduces stockouts, minimizes excess inventory, and streamlines replenishment.

Streamlined Production Processes

RFID technology also helps streamline production processes. By placing RFID tags on work-in-progress (WIP) items and production equipment, manufacturers can track the flow of goods through the production line. This leads to better planning and scheduling, as well as identifying bottlenecks or inefficiencies to address and improve overall productivity.

Real-Time Information

- Know what happened, when it happened, and why.

Operational Flexibility

- Adapt quickly to changing production needs.

Flawless Productivity

- Manage assets and inventory holistically and scale on demand.

Customized Solutions

- Easily customize data exchanges and workflows.

Quality Control and Traceability

Ensuring product quality and traceability is essential, especially in industries like automotive, aerospace, and pharmaceuticals. RFID smart manufacturing solutions help manufacturers implement strong quality control measures. By tracking components and recording production parameters, RFID technology allows for accurate traceability. In the event of a quality issue or product recall, it enables quick identification of affected products and effective corrective actions.

Workforce Optimization

Beyond asset and production management, RFID technology optimizes workforce productivity. By equipping workers with RFID-enabled badges or wearables, manufacturers can track their movements and activities on the shop floor. This data helps analyze workflow patterns, identify process improvement opportunities, and ensure safety compliance.

Looking to the Future

As technology evolves, the applications of RFID smart manufacturing solutions are limitless. Advances in RFID tag miniaturization, sensor integration, and data analytics will enhance RFID capabilities. These advancements promise greater efficiency, agility, and innovation in manufacturing.

As a result, RFID smart production solutions are transforming the manufacturing environment by providing real-time visibility, improving process efficiency, guaranteeing product quality and optimizing workforce productivity. As manufacturers embrace the power of RFID technology, they are poised to gain a competitive advantage in an increasingly complex and dynamic global marketplace.

RFID System Optimizing Rental Vehicle and Equipment Management

In the dynamic environment of rental services, effective management of vehicles and equipment is vital for smooth operations and customer satisfaction. The RFID system, which optimizes the management of rental vehicles and equipment, has led the way by streamlining the processes of systems such as Outline.

Advanced Track and Trace

The Outline RFID system offers a comprehensive solution for tracking and monitoring rental vehicles and equipment in real time. By equipping assets with RFID tags, each item becomes uniquely identifiable, allowing for seamless tracking throughout its lifecycle. This enhanced visibility allows rental companies to precisely locate assets, track usage patterns and prevent loss or theft.

Streamlined Operations

With Outline, rental businesses can streamline their operations by automating various tasks. RFID technology enables automated check-in and check-out processes, eliminating manual procedures and reducing administrative burden. This automation not only saves time, but also minimizes errors, ensuring accurate records of asset movement and availability.

Optimized Asset Utilization

Efficient asset utilization is the cornerstone of profitability in the rental industry. The Outline RFID system enables rental companies to optimize asset utilization by providing insights into usage patterns and demand trends. By analyzing the data collected through RFID tags, businesses can make informed decisions on inventory management, fleet allocation and service planning, maximizing the return on investment for each asset.

Enhanced Customer Experience

A seamless and hassle-free experience is crucial for customer satisfaction in the rental industry. The Outline RFID system contributes to improved customer experience by providing faster and more efficient service. With streamlined processes and accurate tracking, rental companies can fulfill customer requests instantly, minimize waiting times and ensure the availability of the requested vehicle or equipment.

Enhanced Security and Compliance

Security and compliance are critical in rental operations, especially in highly regulated industries such as transportation and construction. The Outline RFID system enhances security by providing tamper-resistant identification and tracking capabilities. In addition, it facilitates compliance with regulatory requirements by keeping detailed records of asset utilization and maintenance history.

As a result, Outline the RFID system that optimizes rental vehicle and equipment management represents a paradigm shift. By leveraging advanced tracking technology, automation and data analytics, rental businesses can optimize operations, improve asset utilization, increase customer satisfaction and ensure compliance with industry standards. With Outline, the future of rental management is smarter, more efficient and safer than ever before.

RFID Tools Tracking

In industries where efficiency, safety, and inventory management are paramount, integrating RFID technology for hand tools tracking is becoming increasingly common. This article explores how RFID tool tracking systems are revolutionizing operations, streamlining workflows, and reducing losses.

Efficiency through Automation

RFID tool tracking automates inventory management, eliminating manual counting and reducing human error. By attaching RFID tags to tools, each item becomes uniquely identifiable within the system. This process allows for quick and accurate identification, and it tracks each tool’s location and condition throughout its lifecycle.

Real-Time Visibility

RFID technology provides real-time visibility into tool usage and availability. RFID readers, placed strategically throughout the plant, allow managers to track the movement of tools in and out of designated areas. This visibility helps supervisors optimize tool allocation, avoid unnecessary delays, and ultimately boost productivity.

Enhanced Security

RFID technology enhances security by preventing tool theft, tracking, and unauthorized use. RFID tags can be programmed to trigger alarms when tools leave designated zones without authorization, helping prevent loss or misuse. Additionally, the system logs all tool movements, enabling the quick identification of discrepancies and investigation of suspicious activities.

Maintenance Optimization

Maintenance programs are essential to ensure tool reliability and extend tool life. RFID tracking systems integrate seamlessly with maintenance management software, automating alerts based on usage data. By tracking usage patterns and monitoring tool conditions in real-time, organizations can implement preventive maintenance strategies, reduce downtime, and lower repair costs.

Enhanced Accountability

With RFID tool tracking, responsibility increases significantly. Each tool is assigned to a specific user or department and its use is recorded accordingly. This accountability encourages responsible behavior among employees, reducing instances of negligence or misconduct. Furthermore, in the event of tool misplacement, RFID technology speeds up the locating process, minimizing disruption to operations.

Conclusion

Incorporating RFID tool tracking systems into industrial operations offers multiple benefits, including improved efficiency, enhanced safety, and optimized maintenance practices. As technology evolves, RFID solutions will likely become standard in industries, leading to continued optimization and innovation in tool management processes.