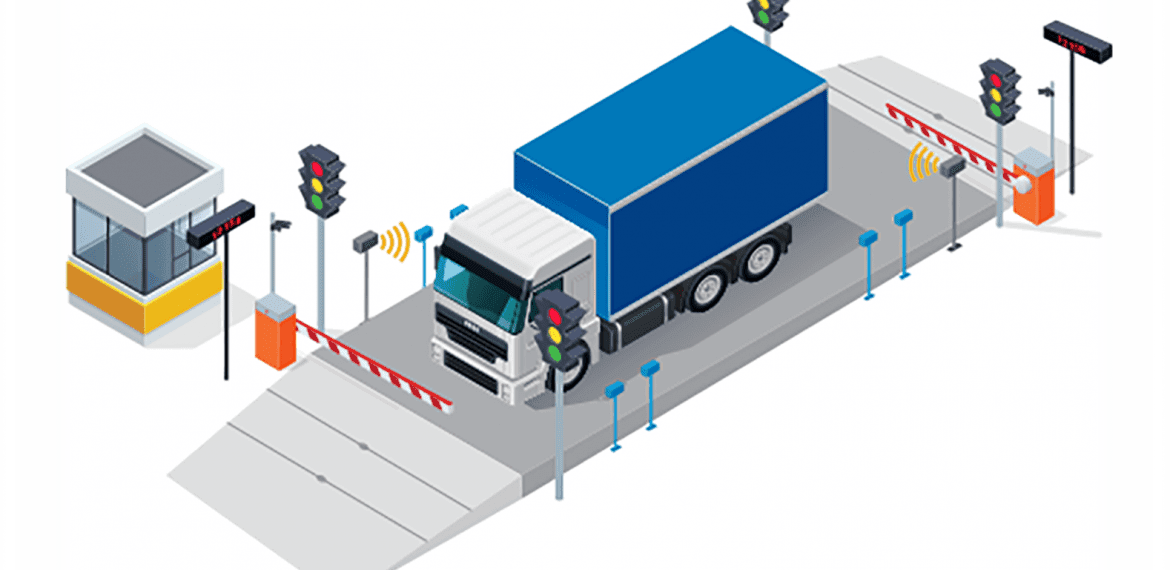

Automated weighing systems are increasingly used to improve efficiency and reduce the margin of error in industrial processes. One technology that enhances the efficiency and accuracy of these systems is Radio Frequency Identification (RFID) technology. In this article, we will explore RFID applications in automated weighing systems and the benefits this technology provides.

Introduction to RFID Technology

RFID technology uses electromagnetic fields to automatically identify and track tags attached to objects. These tags store electronically encoded information that RFID readers can scan without a direct line-of-sight. This feature makes RFID versatile and effective in various environments.

1. How RFID Enhances Automated Weighing Systems

Improved Accuracy and Efficiency

RFID technology enhances the accuracy of automated weighing systems by eliminating manual input errors and allowing precise data collection. This improvement leads to more reliable weight measurements and boosts operational efficiency by reducing the need for manual intervention.

Real-Time Data Collection

RFID enables real-time data collection as products pass through the weighing system. This allows for immediate processing and analysis, speeding up decision-making and providing timely responses to any discrepancies or issues.

2. Applications in Logistics and Supply Chain Management

Inventory Management

In logistics and supply chain management, RFID-integrated weighing systems simplify inventory tracking. As goods move through various stages, their weight is automatically recorded and updated in the inventory system. This ensures accurate stock levels and minimizes the risk of overstocking or stockouts.

Transportation and Shipping

RFID applications in transportation and shipping include automated weighing systems that verify the weight of packages and containers before loading them onto transport vehicles. These systems ensure compliance with weight regulations and optimize load distribution, improving safety and fuel efficiency.

3. Applications in Manufacturing and Production

Quality control

In manufacturing, RFID-enabled weighing systems play a crucial role in quality control. By continuously monitoring the weight of raw materials and finished products, manufacturers can ensure that each product meets the set weight criteria, reducing the possibility of defects and maintaining high quality standards.

Automatic Sorting and Packing

RFID improves automated sorting and packing processes by linking weight data with product information. This enables precise sorting by weight and guarantees accurate packaging. This is crucial in industries such as pharmaceuticals and food production, where precision is critical.

4. Practices in Agriculture and Livestock Management

Crop Yield Measurement

RFID-equipped weighing systems help accurately measure crop yields in agriculture. As farmers weigh harvested crops, the data is automatically recorded, assisting in monitoring productivity and making informed decisions on crop management and resource allocation.

Animal Weighing

In livestock management, RFID technology helps monitor the weight of animals. By attaching RFID tags to livestock, farmers can effectively track animal growth and health by automatically recording weight data during feeding or health checks.

5. Benefits of RFID in Automated Weighing Systems

Enhanced Traceability and Transparency

RFID provides enhanced traceability by linking weight data to specific RFID tags that can contain detailed information about the product or item. This transparency is beneficial for quality assurance, regulatory compliance and customer satisfaction.

Cost Savings and Increased Efficiency

The automation and accuracy brought by RFID technology delivers significant cost savings by reducing labor costs, minimizing errors and streamlining operations. Increased productivity results from faster processing times and reduced downtime.

6. Challenges and Considerations

Integration and Implementation Costs

Despite its advantages, integrating RFID into existing systems can be costly. The initial investment in RFID infrastructure, including tags, readers and software, as well as potential changes to existing processes should be carefully considered.

Data Security and Privacy

With the increasing use of RFID technology, data security and privacy have become critical concerns. Ensuring RFID systems are protected against unauthorized access and data breaches is essential to safeguard sensitive information and maintain trust.

7. RFID and Future Trends in Automated Weighing Systems

Developments in RFID Technology

Continued advances in RFID technology, such as increased read ranges, enhanced data storage capabilities and improved durability of tags, will further expand the applications and effectiveness of RFID in automated weighing systems.

Integration with IoT and Artificial Intelligence

The integration of RFID with the Internet of Things (IoT) and Artificial Intelligence (AI) promises to bring even greater innovation. IoT connectivity enables seamless data sharing between systems, while AI can optimize operations and decision-making by delivering advanced analytics and predictive insights.

Solution

RFID applications in automated weighing systems are transforming industries by providing accurate, real-time data, increasing efficiency and enabling traceability. As technology continues to evolve, the potential for RFID in weighing systems will grow, providing new opportunities for innovation and improvement across a variety of industries.