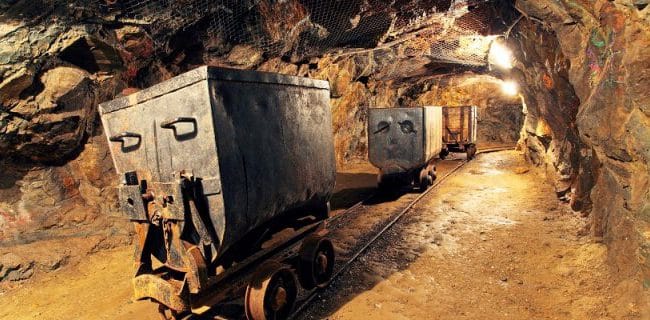

The use of RFID in the mining sector has become increasingly popular in recent years. In this article, we will give you information about how it is used and its application areas. The mining sector has long been a critical component of global economies, providing valuable resources used in various industries and sectors. Recently, RFID in the mining sector has provided numerous benefits and changed the shape of mining operations.

WHAT IS RFID?

RFID is a wireless communication technology that uses radio waves to transfer data between the reader and the tag. Tags are small, durable devices that can be affixed to objects, vehicles or personnel and contain unique identification information. RFID readers are devices that can communicate with and collect data from RFID tags. When an RFID tag enters the range of an RFID reader, the data stored in the tag is transmitted to the reader, enabling real-time tracking and monitoring of assets and personnel.

RFID Applications in the Mining Industry

One of the primary applications for RFID in the mining industry is asset tracking and management. In large mining operations, equipment, vehicles and tools are critical assets that must be tracked and efficiently managed to ensure smooth operations. RFID tags can be attached to these assets, allowing them to be accurately tracked and located in real time. This helps mining companies optimise asset utilisation, reduce equipment downtime and improve maintenance scheduling. RFID technology also enables automated inventory management as tagged items can be automatically scanned and recorded. This eliminates the need for manual counting and reduces human error.

Safety is a top priority in the mining industry and RFID has been instrumental in the development of safety measures. RFID tags can be worn by miners as personal protective equipment (PPE). This enables real-time monitoring of their location and ensures compliance with safety regulations. In the event of a collapse or gas leak, RFID technology can help miners to be found quickly. It can shorten response time and minimise potential damage. RFID-enabled access control systems reduce the risk of accidents by preventing unauthorised access to restricted areas.

RFID is also mainly used in maintenance and repair operations in the mining industry. Equipment maintenance is critical to mining operations, as failures can lead to costly downtime. RFID technology provides real-time data on equipment utilisation, performance and condition. This helps automate maintenance processes. RFID tags can be attached to equipment parts or components. This allows them to be easily identified and tracked. This enables predictive maintenance, where equipment problems can be detected early based on RFID data, allowing timely repair or replacement. This approach enables mining companies to optimise their maintenance programmes.